checking fixture design guidelines

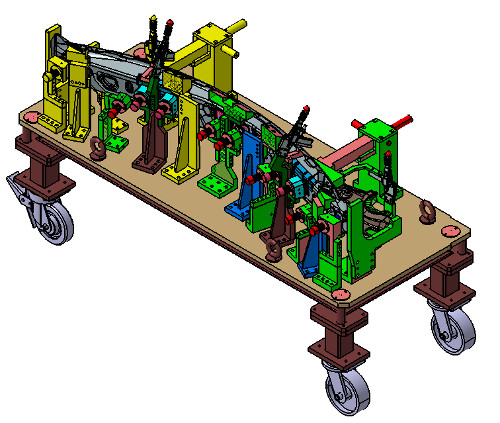

To design and build a high performance test system an engineer must understand how the measurement signals will travel from the instrument to the pins that touch the product under. Base plate must fully encapsulated the part and any swing out details in their fully opened position.

Week 3 Biw Fixture Design Methodologies Challenges

Specific constraints for each shop will again be identified.

. Domain courses include CAD with engineering fundamentals like material selection manufacturing process design. For example pipe-sizing requirements that were set more than 50 years ago remain unchanged even though plumbing fixture flow rates flush. Checking fixtures and CMM holding fixtures are tools that dimensionally qualify detail parts or assemblies and audit manufacturing process variations.

All checking fixtures must have four tapped holes M16 present on the base plate. But how can you manage a holiday with a baby and all her gear in tow. 511 All check Fixtures are to be quoted as design and build.

Final details are decided final drawings are made and the tooling is built and testedThe following guidelines should be considered during the final-design process to make the fixture less costly while improving its efficiency. If the base plate exceeds 60 in length the location of the tapped holes should be 600mm from the center in both direction. Checking fixture design guidelines Written By louiezoldak24685 Friday April 22 2022 Add Comment Edit If the checking fixture were to exceed the CMM table size additional feet will be needed to sit level.

Easily distinguished from other planets by its. This document is intended as a guideline to make fixture sources aware of the build requirements and buyoff criteria that will provide the basis for fixture approval and invoice payment. All quotes for new gages and engineering changes are to be based on these Minth Check Fixture Tooling Standards.

No planet has captured our imaginations more than Mars. The des ign and creation of the 2D and 3D of the project. Phase I 2 actual practical development at Tinker will be drawn.

All quotes are to have the following statement on them. Base plate must fully encapsulated the part and any swing out details in their fully opened position. The check fixture is a form.

522 the fixture concepts shall accurately show the intent of the design how the part will nest datum locations types of checks clamp locations etc in a manor that is consistent with the geometric dimensioning and tolerancing of. 2We can create checking fixture specification considering located parts in each car manufacturing process. These rules are a mix of practical considerations sound design practices and common sense a.

Checking Fixtures must be design to allow measurements with horizontal arm CMM with the above working envelope. Checking fixture design guidelines Written By marcmassaquoi341 Saturday June 11 2022 Add Comment Edit Design verification is the most important aspect of the product development process illustrated in Figures 13 and 15 consuming as much as 80 of the total product development timeThe intent is to verify that the design meets the system. ¾ Check fixture less than 10 lbs requires no feet check fixture 10-30 lbs requires feet and a check fixture more than 30 lbs requires 2 high risers.

62 In the absence of a qualified stamped base checking fixtures are to be provided with three tooling. And must be etched or steel stamped on checking fixture. Final details are decided final drawings are made and the tooling is built and testedThe following guidelines should be considered during the final-design process to make the fixture less.

A check fixture is a conventional tool for verifying that a bent tube or tubular assembly conforms to the print. Compliance to these requirements is mandatory for all involved parties. Identify material being used in stock list by detail.

Checking Fixture Design Guidelines. This project researched standard principles. 114 Fixture Design Fundamentals.

This handbook is a multi-chapter illustrated reference manual featuring step. They are the most common type of fixture because their versatility makes them adaptable to a. This alignment can be geometric or by 3 centres.

This document is intended as a. Fixture Design Fundamentals of Tool Design Study Guide DV07PUB3 - 2 - Fixture types fall generally into five groups. We are specifically dealing with Toyota as our end customer.

The materials to be used the elements of metrology to be included and the surface and heat treatments. UNIT 4 DESIGN OF FIXTURE Design of Fixture Structure 41 Introduction Objectives 42 Design of Fixtures 43 Types of Fixture and its Industrial Application 431 Vise Fixture 432 Milling Fixture 433 Facing Fixture 434 Boring Fixture 435 Face Plate Fixture 436 Turning Fixture 437 Grinding Fixture 44 Summary 45 Key Words. 521 fixture concept must be submitted to bae within one week after kick off of any new check fixture.

4 of them are engineers with the related working experiences for minimum 5 years. This document is intended as a guideline to make fixture sources aware of the build requirements and buyoff criteria that will provide the basis for fixture approval and invoice payment. Up to 24 cash back Checking fixture design guidelines.

Jigs and fixtures have an undeniable role in the overall art of metalworking. Today this process is primarily handled with advanced technology like CNC machines. Checking fixture design guidelines Written By curtbrandenburger41730 Sunday May 15.

Checking fixture design guidelines Written By arethaquain36025 Friday May 6 2022 Add Comment Edit. The definition of a checking fixture will have important consequences on. A check fixture also can accommodate tools or equipment for drilling holes trimming the ends or in this case orbital welding.

Quoted to the Minth Check Fixture Tooling Standards Rev 4 Dated 91019 3. Plate Fixtures Plate fixtures are constructed from a plate with a variety of locators supports and clamps. Factors to be considered for design of Jigs and Fixtures 1.

All new gage costs are to itemized and include the following. 62 In the absence of a qualified stamped base checking fixtures are to be provided with three tooling. Checklist for Check-Fixtures Automotive Check Fixtures - Injection Molding thenson Mar 5 2009 T thenson Starting to get Involved Mar 5 2009 1 Our company is rather new with automotive checkfixtures design concepts construction and qualification.

E t The manufa cture of every lemen of the checking fixture. This paper prese nted a fixture layout design shown in fig. Hence a step-by-step procedure for jig and fixture design will be developed.

The Jigs and fixtures design as well as the clamping support and locating technique of your machine setup must work in tandem to create flawless products or prototypes. Using this a formal generalization of the concepts and methodologies of fixture design for Tinker will be developed.